KLB basement masonry and seals

So you always have a dry basement

When using KLB wall building materials in the basement area all requirements of DIN 1053-1 are fulfilled without problems. The minimum wall thickness for exterior basement walls is 240 mm, for KLB dry masonry 300 mm. The butt joints of KLB blocks remain non-mortared for basement masonry as well.

Due to the high permitted stresses, KLB flat block masonry is particularly suited for creating highly stressed exterior basement walls. For exterior basement walls with minor load but high earth backfill, e.g. in the area of terraces, a ring beam made of KLB U-blocks at half the wall height can make sense for receiving the load if the appropriate proof is provided.

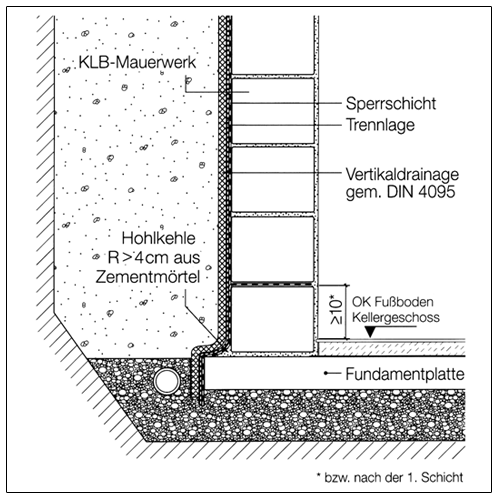

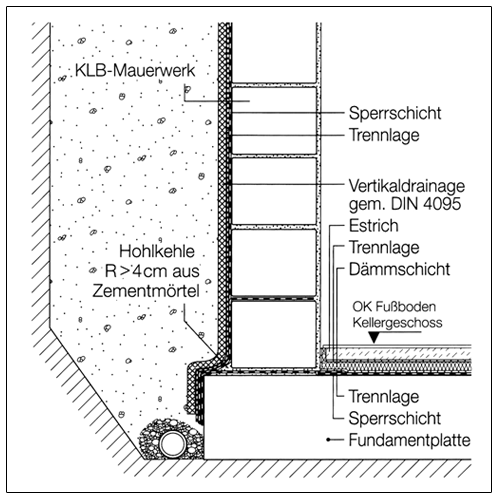

The rough surface of the KLB-blocks is an ideal adhesion base for moisture blocking measures. For vertical and horizontal sealing of the basement masonry DIN 18 195 is decisive. All wall surfaces touching the ground must be sealed against moisture. The seal must be maintained below up to the start of the foundation and above up to the horizontal seal.

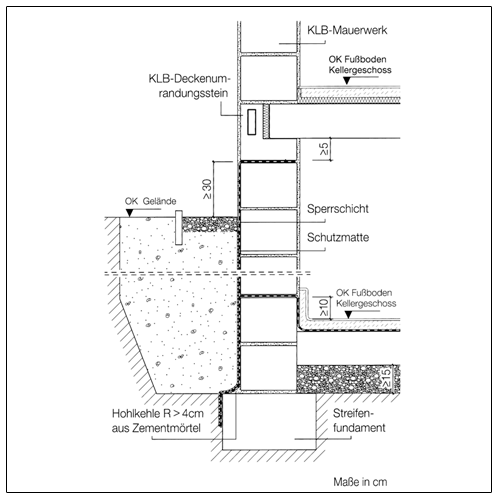

For protecting the vertical insulation from damage when backfilling the earth a building protection mat should be ordered. The earth may only be backfilled when the required wall load exists.

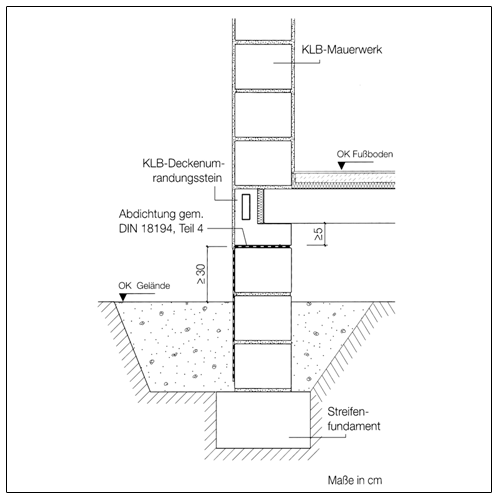

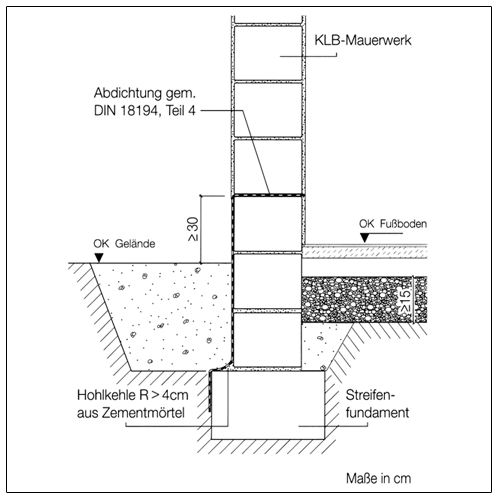

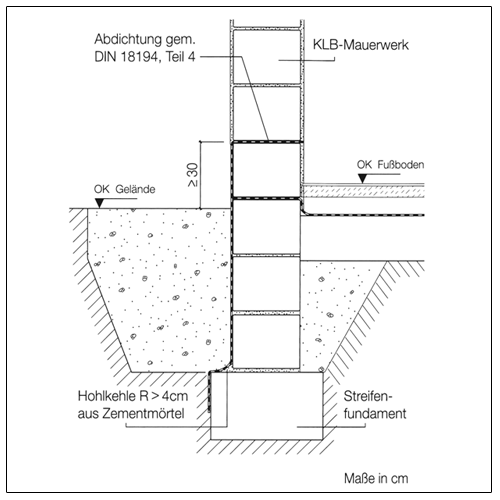

Buildings without basements are protected by horizontal seals in the exterior and interior walls against rising moisture. In exterior walls the horizontal barrier is about 30 cm above the terrain. All exterior surfaces touched by the ground must be sealed against moisture. The ground slab must also be sealed, if it does not have a ventilated interim space to the ground. If the rooms bordering the ground are not used for living purposes, a capillary interrupting fill e.g. of rough grained gravel of ≥ 15 cm thickness can protect against the introduction of moisture instead of the seal.

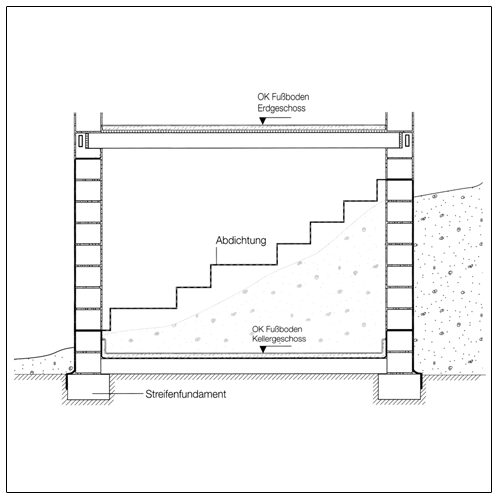

Brick-walled exterior basement walls receive at least two horizontal seals. The lower seal runs about 10 cm above the basement floor, and the upper seal must be aligned about 30 cm above the terrain. For interior walls the upper seal can be omitted. The basement ceiling must lie with its bottom side ≥ 5 cm above the upper horizontal barrier. If the cellar ceiling, e.g. in case of hill locations, lies deeper, a third horizontal seal is required.

All exterior surfaces touched by the ground must be sealed against moisture. The basement floor must be sealed as in buildings without basements. For lower storey walls a ring drainage is recommended in addition to the seals.

For the horizontal seals in the walls, bitumen roof sheeting and sealing sheets or plastic sealing sheets are used. The seals must consist of at least one layer and must not be glued. At butts the sheets must overlap at least 20 cm. Unevenness must be levelled with mortar.

For the vertical seals of the exterior wall surfaces mostly covering paints, putty or asphalt mastic are used. Masonry areas must be built completely filled and bonded to receive seals. If necessary, the areas must be levelled and plastered with mortar. For non-mortared butt joints with full interlocking, depending on the sealing agent, a complete trowelling of the exterior wall surfaces with mortar may make sense. For sealing floor surfaces bitumen sheets, plastic sealing sheets or asphalt mastic is used.

Buildings are sealed against non-pressurised water, e.g. precipitation, seepage or service water, which does not place any pressure on the seal, with bitumen substances, plastic sealing sheets or metal bands. For sealing against pressurised water, e.g. hill or groundwater, a closed basing made of concrete must be formed.

The leaflet “Sealing Masonry Touching the Ground” by the German Association for Masonry provides implementation tips for sealing masonry, specifically in the basement area. The following sealing methods are described: Waterproofing slurries, bitumen sealers and sealing sheeting. The 24-page leaflet can be downloaded as a .pdf at www.dgfm.de free of charge.