Use of KLB supplementary products

KLB supplementary products are the cherry on the top of the KLB modular construction system.

By using them properly, in a targeted manner, you get homogeneous walls even where other construction materials force you to choose time and cost intensive constructions.

- Stop blocks

- Bay blocks

- Ceiling partition

- U-blocks

- shutter boxes

KLB stop blocks

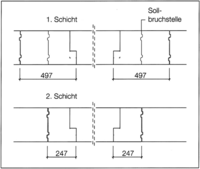

KLB stop blocks are available for wall thicknesses 30.0 cm (20 DF) and 36.5 cm (12 DF). KLB stop blocks are divisible at half their length. The limits for the 30-type block as well as the 36.5-type block are 6/12 cm. The limits can simply be reduced to 6/6 cm using a mason’s axe on the construction site. If roller shutter boxes are planned for over exterior windows and doors, the limit must be reduced to the 6/6 cm dimension.

Compared to the production of stops with small-format blocks built in a bond, the use of KLB stop blocks results in a working time saving of 0.2 h/m per facing. KLB stop blocks must as a rule be laid in a stretching bond with half-block overlaps.

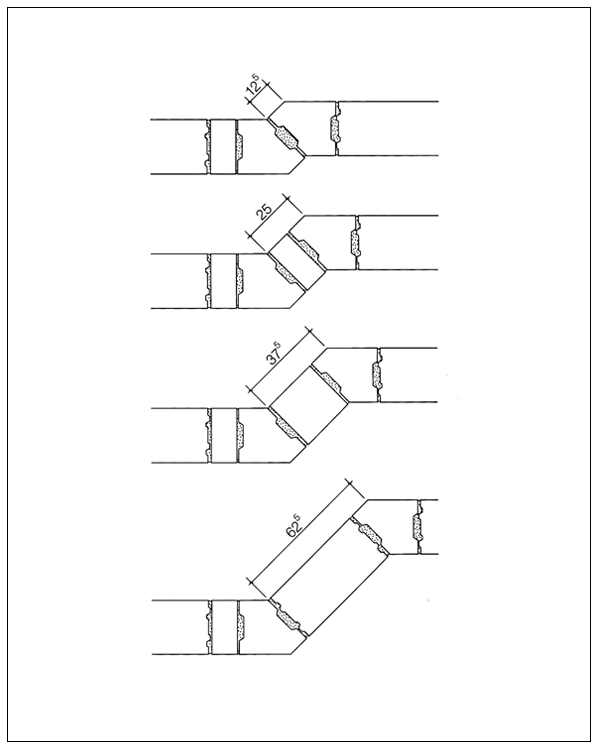

KLB bay blocks

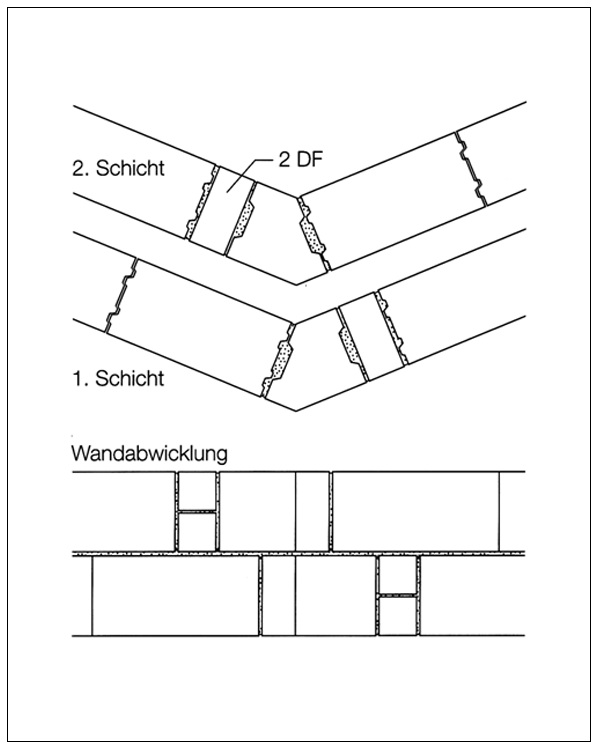

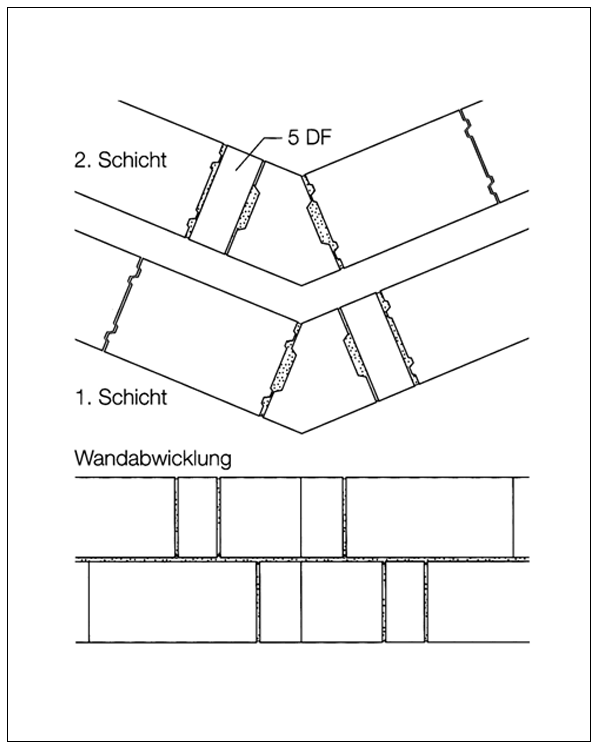

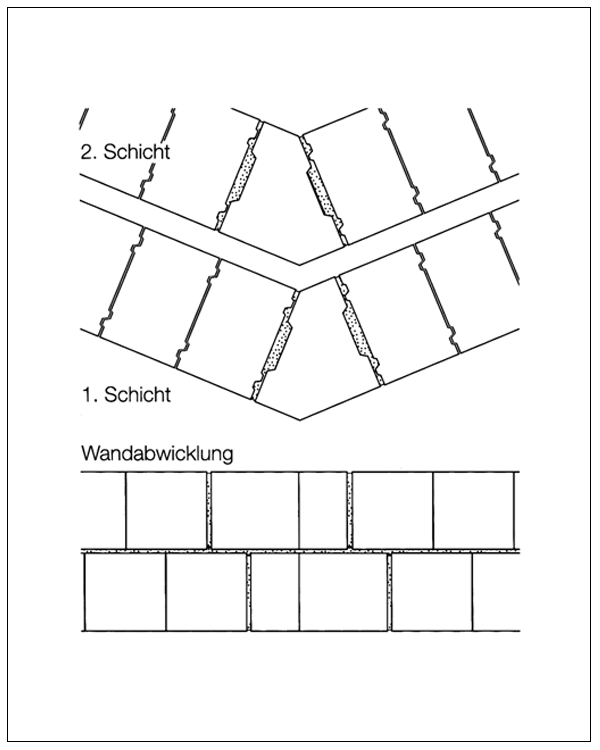

KLB bay blocks allow the problem-free creation of 24, 30 and 36.5 cm thick, angled masonry with angles 45° or 135° respectively. This eliminates the adjustment to slants at the construction sites via time-intensive and cost-intensive cutting or masonry.

KLB bay blocks are processed alternatingly while rotating by 180°. For this reason they do not have tongue and groove formation in the butt joint but face side pockets, which must be mortared. The length of the KLB bay blocks is selected such that on one side there is a half-block bond, and on the other side a quarter-block bond.

KLB ceiling partition

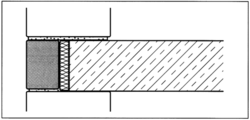

KLB ceiling partition blocks, non-insulated, serve to partition the ceiling only. They can be delivered for ceiling thicknesses of 16 cm to 22 cm. The associated gross density class is 1.2. The heights of the KLB ceiling bricks with 1 cm bed joint mortar each give the height of the raw ceiling. Concrete work on the corresponding ceiling has to wait until the mortar has set and is hard enough for the blocks not to loosen during concrete work.

KLB ceiling partition blocks are processed like KLB solid blocks along the entire joint with the butt and horizontal joint. The same mortar is to be used as in the masonry below it. At the construction site a continuous insulation layer with a thickness of 6 cm should be inserted between the ceiling partition and the ceiling to have concrete work done on it in order to prevent thermal bridges.

KLB ceiling partition blocks, insulated, serve to partition ceilings and are available as partition blocks with a system length of 100 cm for the ceiling thicknesses from 15 cm to 25 cm. The insulated KLB ceiling partition blocks have an 8 cm thick styrofoam insulation, which is held by an L-shaped, thin light-weight concrete shell. The light-weight concrete surface pointed outward offers an equally good plaster base as the remaining masonry.

KLB ceiling partition elements offer an improvement with regard to thermal technology over the insulated partition blocks. They consist of an exterior, plaster-capable light-weight concrete shell with a moulded 100 mm thick thermal insulation. KLB-ceiling partition elements are available for ceiling heights of 18 cm, 20 cm and 22 cm.

For the insulated KLB ceiling partition blocks and elements this results in a joint height of about 1 cm the height of the raw ceiling. In the butt joint the ceiling partition blocks and elements are bumped bluntly against one another without mortaring.

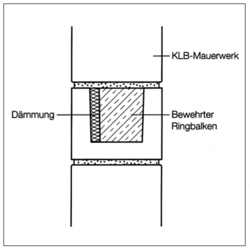

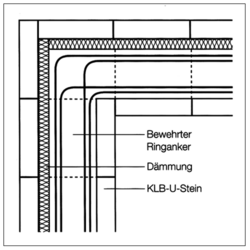

KLB U-Blocks

KLB U-blocks are versatile elements for wall thicknesses of 17.5, 24.0, 30.0 and 36.5 cm. The associated gross density class is 1.0. For 30.0 and 36.5 cm thick exterior walls U-blocks of gross density class 0.6 can also be delivered. KLB U-blocks make time consuming shell work superfluous, for example when forming ring anchors or ring beams, building pillars or surrounding supports. They serve as lost formwork for support padding, anchors for roof purlins as well as for steel concrete lintels to be created on-site.

When exterior basement walls only bear minor loads (e.g. for prefabricated houses), or if the dirt backfill is supposed to occur prematurely, horizontally aligned beams made of KLB U-blocks bracket the basement walls at half the height of the storey. At the construction site reinforcement rods are inserted and the hollow space is filled in up to the upper edge with concrete. The available concrete cross section is for KLB U-blocks with the width

- 175 mm = 9,5 x 18 cm

- 240 mm = 12,0 x 18 cm

- 300 mm = 18,0 x 18 cm

- 365 mm = 24,5 x 18 cm.

For exterior walls an insulation layer inserted at the construction site (pointing outwards) prevents possible heat bridges

Installation of roller shutter boxes

KLB roller shutter boxes can be delivered upon request depending on the manufacturing length up to a total length of 3.25 m. The delivery of the KLB roller shutter boxes occurs in dimensions of 101 cm to 326 cm in length intervals of 25 cm. Special dimensions up to a length of 6.60 m upon request. The boxes are dimensionally stable even for longer lengths and thanks to their low weight they allow affordable installation without requiring a construction crane.

The required support length is on both sides 12.5 cm each. This means the total length of the individual roller shutter box to be ordered results from the clear opening dimension of the window or the window door plus 25 cm.

When building the exterior masonry with window and roller shutter box it must be clarified in advance whether the roller shutter to be installed will be operated later using a belt pull or a motor. In case of a belt pull a KLB belt winding box must be installed taking into account the installation side desired by the developers.

KLB roller shutter boxes are built into a fully jointed light-weight mortar bed above the opening onto the masonry on both sides, taking into account the above-mentioned support length and aligned horizontally and vertically. On the outside the roller shutter box is flush with the masonry. Afterwards continue with the masonry work by placing the blocks at the head ends of the roller shutter box fully jointed with light-weight mortar.

Before setting a lintel or the slab ceiling the EPS roller shutter boxes with lengths 1.50 m must be supported over their entire surface. Point loads on the unsupported roller shutter boxes, such as placing things on them, must be avoided. Equivalent to the mortar spread for the lintel on the blocks a continuous, fully jointed layer of mortar must also be spread on the roller shutter box. If the ceiling starts directly above the roller shutter box the concrete bonds with the box via the empty joint located at the upper box side. After hardening of the mortar or concrete the support can be removed.

After installation of the window and before the installation of the roller shutter slats the KLB roller shutter box must be opened with a hole drill if a belt pull is used as an extension of the belt winding box and the energy saving and noise insulating belt guide, to be ordered separately, must be inserted with plaster protection and brushes. Upon request a so-called window divider can also be ordered separately and installed, so e.g. in the living room two roller shutters for window and window door can be moved separately.

If the window opening happens to be smaller than planned, the box can be shortened after taking off a headpiece on the box at any time on-site at the construction site.