Building joints

Notes on installing expansion and separation joints

Due to different deformations of the masonry (e.g. length changes) masonry can be produced with infinite lengths. This means that when cracks are to be avoided, expansion joints are to be planned at appropriate intervals and formed constructively. As rule of thumb for a crack-free wall length a 3-fold clear wall height applies for load-bearing walls, the twofold clear wall height for non-load-bearing walls.

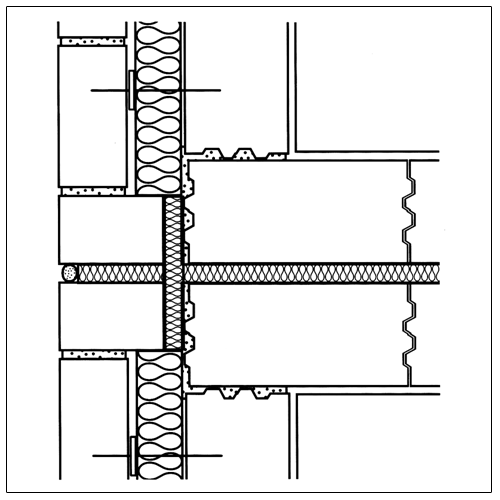

The width of the joints orients itself by the form changes of the component to be expected and the deformation ability of the used joint closure material. As a rule 5 to 7 times the change in length is to be assumed as the joint width. In practice joints between 15 and 25 mm are selected and the joint distances are adjusted accordingly. Measurement and execution of the expansion joints orient themselves according to DIN 18 540.

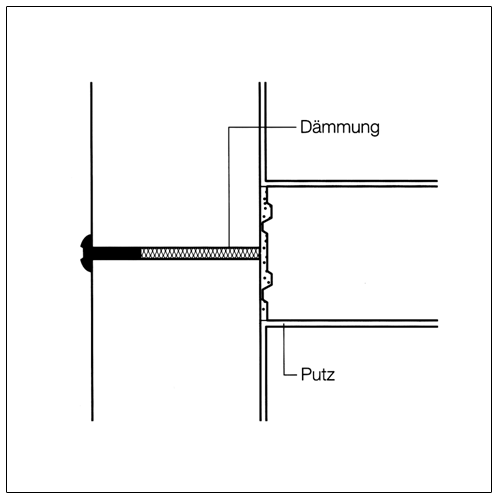

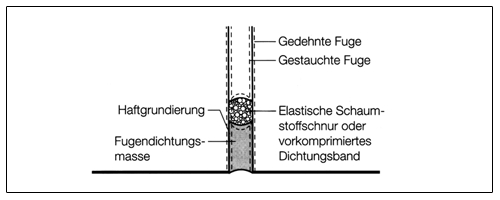

The joint remains free of mortar or is filled with mineral fibre strips. About 40 mm from the exterior edge non-water-absorbing, closed-cell foam strings are pushed in and the remaining exterior joint space is rough cast with joint seal mass. The common joint closure masses are permanently elastic and permanently elastoplastic single and double component masses such as silicon rubber, polyurethane or acrylic dispersions. All sealing masses may only be processed during dry weather. The flanks of the joints must be cleaned in advance of mortar residue and dust. It is recommended to pretreat the joint surfaces with system-compliant primers.

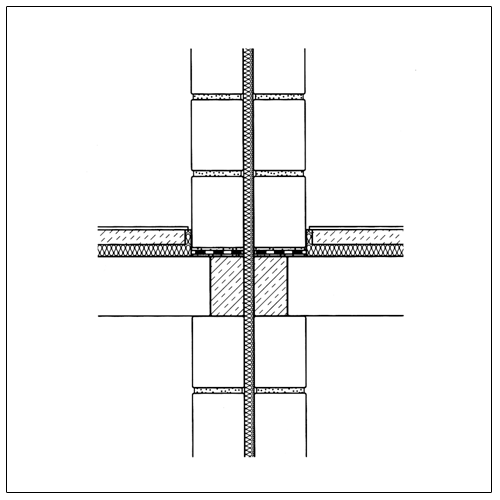

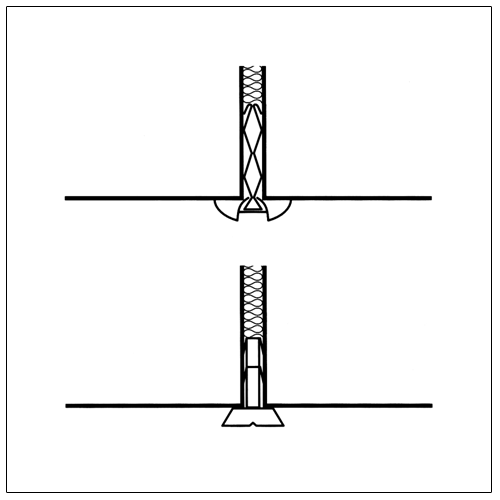

Another option for joint closure are pre-compressed sealing bands, which are laid into the entire joint and push against the joint flanks. For the exterior closure of these sealing bands, but also for the above-mentioned options, cover profiles are suitable that are clamped into the joint. These joint cover profiles are also used for house separation walls and prevent noise transfer from one wall to another.

Building separation joints must be adhered to in particular for house separation walls because of the required noise protection. Although filling the joint with insulation material (low dynamic stiffness), can be omitted for wall weights ≥ 200 kg/m² of the single shells, practice has shown that by inserting insulation material sound bridges, e.g. via mortar, can be prevented.