Processing of KLBQUADRO

A solution for fast, efficient and flexible as well as on-time construction

KLBQUADRO is the large format for realising ambitious construction schedules, making it a solution for fast, efficient as well as flexible and on-time construction with large format masonry. Here the early consideration of this construction method already in the planning phase is of great benefit, but not a mandatory prerequisite.

As with other large format rational system construction methods, KLBQUADRO requires the use of appropriate placement or assembly devices for utilising the full potential. Drivable mini cranes serve as transfer tools on the respective storey ceiling . Different transfer claws are used for picking up the load. These are designed such that simple adjustment allows all blocks and block sections to be handled, without exchanging the claws. Transfer tools and claws can be rented through the construction machine trade for the duration of the building project.

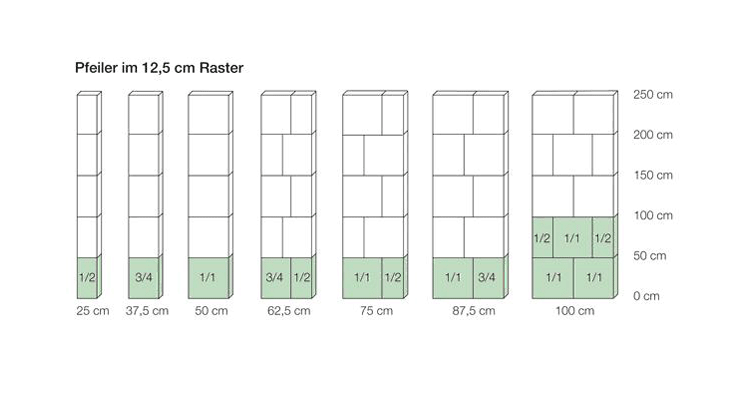

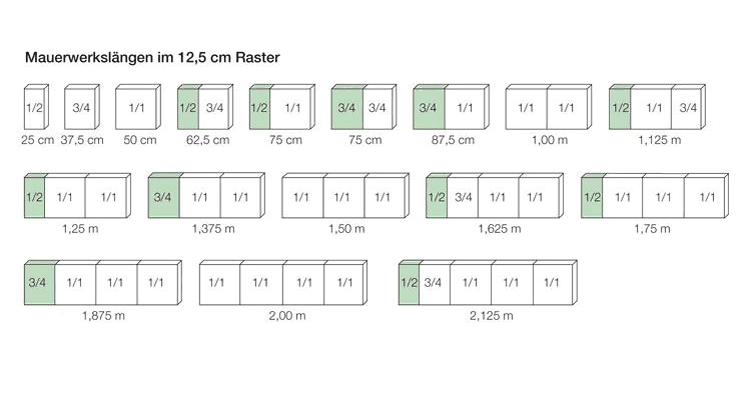

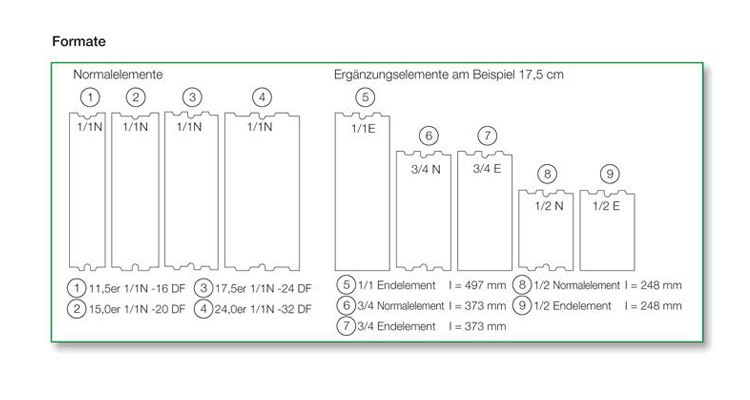

Two men per transfer tool work as a work team. The mason spreads the mortar, sets the blocks swung in using the mini crane and aligns them. The second man, usually a construction helper, operates the transfer tool and provides the needed blocks, block segments and the mortar. KLBOUADRO flat elements are no longer cut to length or divided at predetermined breaking points, but supplemented by additional elements of the same height with lengths of 373 mm or 247 mm. Thanks to these intermediate lengths half-height masonry in 25 cm or 12.5 cm steps is achievable.

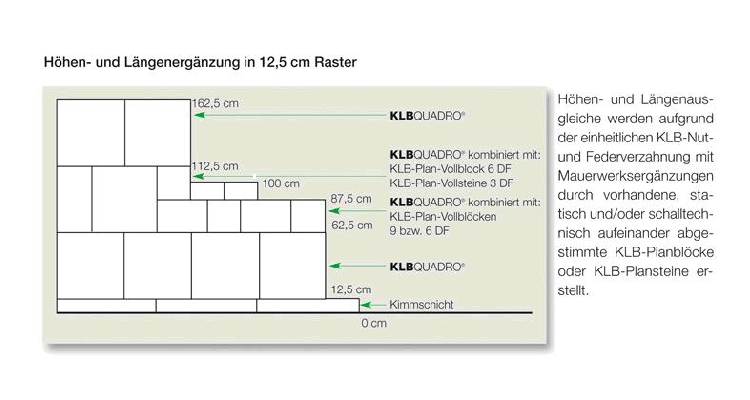

Non-modular dimensions, offset layer, height and length balance are mostly created using masonry supplementations via existing, statically and acoustically coordinated precision blocks and precision stones, so expensive cuts are generally not required. Height and length offsets are created based on the uniform KLB tongue and groove interlocking with masonry supplements using existing, structurally and/or acoustically coordinated KLB flat blocks or KLB flat stones.

In addition to the required mini-crane, which can move two blocks at once, the individual KLBQUADRO flat element can also be moved manually by two masons thanks to its manageable size and weight. The wall integrations are handled using butt joint technology per perforated connecting strip in every position. The masonry connection must be mortared interlocking. Additional priming of the surfaces before plastering is not necessary.