Plugs in KLB masonry

Attachments in KLB masonry

Heavy or recurring load-bearing objects such as wall cabinets or sanitation parts can be attached to KLB walls using plugs without a problem. Since plug anchors and attachments are not regulated in standards, dowels and their application, which are used for load-bearing constructions (anchoring of facing shells, claddings, exterior components), must be approved by the building authority.

As a rule, there are no load-bearing structures and no particular sources of danger in the case of interior components that are attached to walls (wall cupboards, shelves, wall cladding), so that this area remains outside the supervision of the building authorities.

Dowels are distinguished by the anchoring of the dowels in the drill hole, e.g. mechanical spreading, knot formation, friction, mortaring etc. as well as according to the dowel material (metal, plastic). For KLB masonry in the finish area commercially available dowels are usually sufficient. Due to the increased number of slots or chambers lying behind one another in KLB solid blocks SW1, KLB climate light-weight blocks W3 or KLB hollow blocks the length of the spreading dowels must be selected such that the spreading can take effect on several interior channel walls at the same time. Only in this way can the tensile forces occurring be absorbed by the anchor and safely transferred into the lightweight concrete of the block.

The most recently developed knot dowels have proved particularly successful. When retracting the screw the closed tip of the plastic dowel, which is only split in the middle or into thirds, is grabbed by the tip of the screw and pulled together. On the inside of the external ridge of the block a knot-shaped bulge forms that prevents the dowel or the screw respectively from being able to slip out of the masonry, and pulling it out without destruction is hardly possible.

Basically the following notes apply to KLB wall building materials:

- Do not drill in the “impact drilling mode”

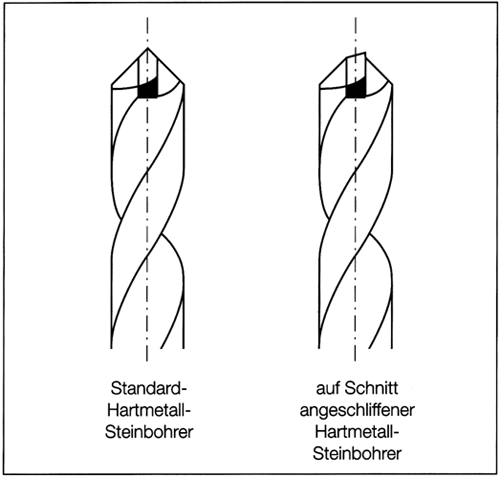

- Use a hard metal masonry drill ground for cutting

- Drill at a slight angle from top to bottom

- Dowel size = drill size = hole strength

- Dowel length = dust free drill hole depth.